I've been reloading for a few years but only sporadically, both rifle and pistol. Like many things, I don't spend enough time at it to get good at it. My loads are always pretty inconsistent, sometimes wildly so, at least compared to factory ammo.

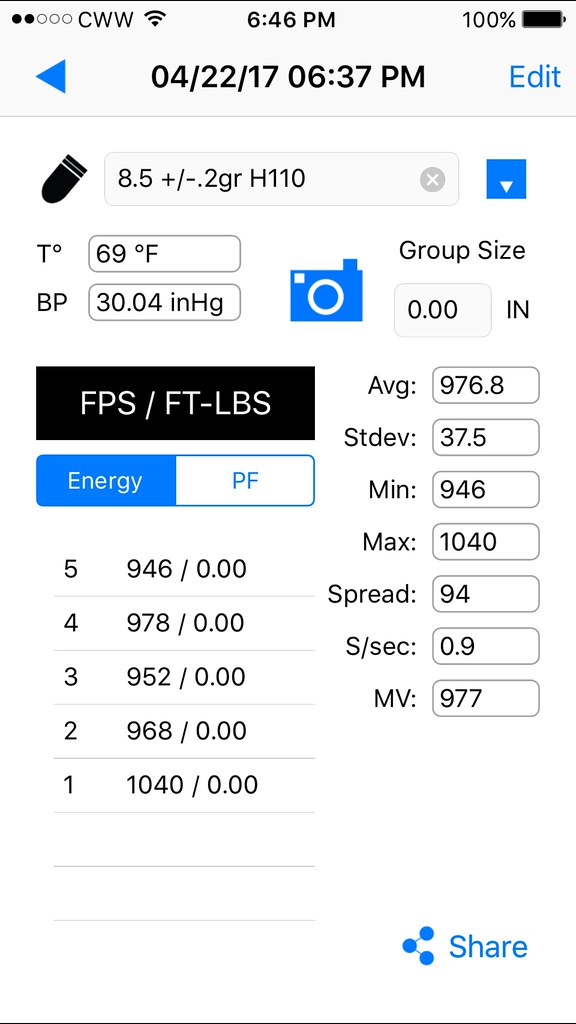

Labor day I was at my range taking my first shots with my new Ruger American in 300blk. I had a few Remington subs and some of my own I had loaded with coated 220gr over 7 to 7.8gr in .2gr increments, five of each. My StdDev=22fps, Spread=50fps approximately for 5 shot groups while the factory loads were 1/10 of that.

I weigh every charge using an inexpensive digital scale. It could be the scale but I just think there might be more going on, like inconsistent neck tension or crimp, etc.

I suspect the scale because I notice the tare value wavering .1-.2gr sometimes before I set the powder cup back on it but it always returns to zero. Would an inaccuracy of .1-2gr cause that much deviation?

Anyone have any suggestions as to the best place to start?

Labor day I was at my range taking my first shots with my new Ruger American in 300blk. I had a few Remington subs and some of my own I had loaded with coated 220gr over 7 to 7.8gr in .2gr increments, five of each. My StdDev=22fps, Spread=50fps approximately for 5 shot groups while the factory loads were 1/10 of that.

I weigh every charge using an inexpensive digital scale. It could be the scale but I just think there might be more going on, like inconsistent neck tension or crimp, etc.

I suspect the scale because I notice the tare value wavering .1-.2gr sometimes before I set the powder cup back on it but it always returns to zero. Would an inaccuracy of .1-2gr cause that much deviation?

Anyone have any suggestions as to the best place to start?

Untitled

Untitled Untitled

Untitled