RacerX

Professional Knucklehead; aka Jeffncs / RacerX

2A Bourbon Hound OG

Charter Member

Vendor

Supporting Member

So I started to shift gears towards the 65 convertible, when my wife reminded me that the Jeep still has a sewing machine engine while the replacement sat on an engine stand for 2+ months. (Thanks again @SDIVER2006 !!!)

So… I decided to bump my 4.0 EFI swap ahead of turning the first wrench in the mustang.

Current state:

1982 Jeep CJ7 258ci/4.2l engine, 5 speed and 3.73 gears front and rear.

The is running a new Weber carb, leaks like a stuck pig and has ~200k miles. It can barely get out of its own way.

The previous owner installed a skid plate spacer kit to help the driveshaft angle, but makes accessing the rear balve cover bolt IMPOSSIBLE,

Future state:

4.0 with the EFI, computer, harness and ECM. Otherwise keeping the stock driveline.

Plan of attack:

External, electric fuel pump - 55gph sourced from Amazon

Harmonic balancer with Crank Position Sensor conversion from Hesco

Speedo cable adapter and Variable Speed Sensor for computer from Hesco

Throttle cable adapter also from Hesco

Stainless steel exhaust manifold - eBay

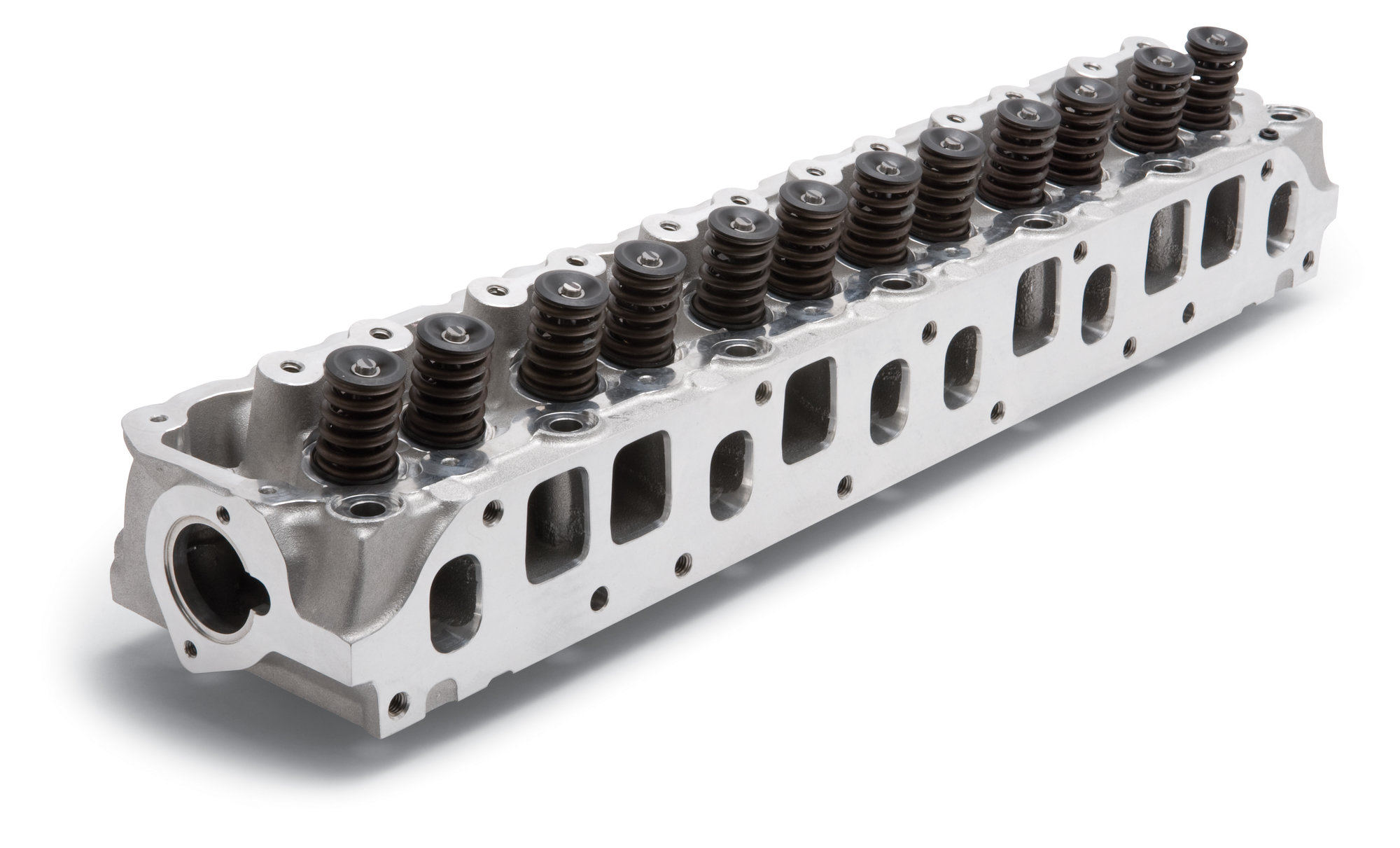

4.0l Engine condition:

~200k miles but ran strong, no oil burn

Stock, fresh engine rated at 190hp (vs 95hp for my 4.2l) - even if a little tired, I’ll still have a substantial power boost

Valve train clean with ZERO sludge

Oil pan spotless and remaining oil clean, healthy brown

Current state:

Stripped the long block and shot it with semi-gloss black engine paint

Replaced the valve cover gasket with a rubber Fel-Pro

Installed a new timing gear set (cracked the cover when installing the last bolt!!)

Pending a buddy to weld the cover

Have a new, rubber Fel-Pro oil pan gasket

I love this stuff!!

So… I decided to bump my 4.0 EFI swap ahead of turning the first wrench in the mustang.

Current state:

1982 Jeep CJ7 258ci/4.2l engine, 5 speed and 3.73 gears front and rear.

The is running a new Weber carb, leaks like a stuck pig and has ~200k miles. It can barely get out of its own way.

The previous owner installed a skid plate spacer kit to help the driveshaft angle, but makes accessing the rear balve cover bolt IMPOSSIBLE,

Future state:

4.0 with the EFI, computer, harness and ECM. Otherwise keeping the stock driveline.

Plan of attack:

External, electric fuel pump - 55gph sourced from Amazon

Harmonic balancer with Crank Position Sensor conversion from Hesco

Speedo cable adapter and Variable Speed Sensor for computer from Hesco

Throttle cable adapter also from Hesco

Stainless steel exhaust manifold - eBay

4.0l Engine condition:

~200k miles but ran strong, no oil burn

Stock, fresh engine rated at 190hp (vs 95hp for my 4.2l) - even if a little tired, I’ll still have a substantial power boost

Valve train clean with ZERO sludge

Oil pan spotless and remaining oil clean, healthy brown

Current state:

Stripped the long block and shot it with semi-gloss black engine paint

Replaced the valve cover gasket with a rubber Fel-Pro

Installed a new timing gear set (cracked the cover when installing the last bolt!!)

Pending a buddy to weld the cover

Have a new, rubber Fel-Pro oil pan gasket

I love this stuff!!