Congrats!

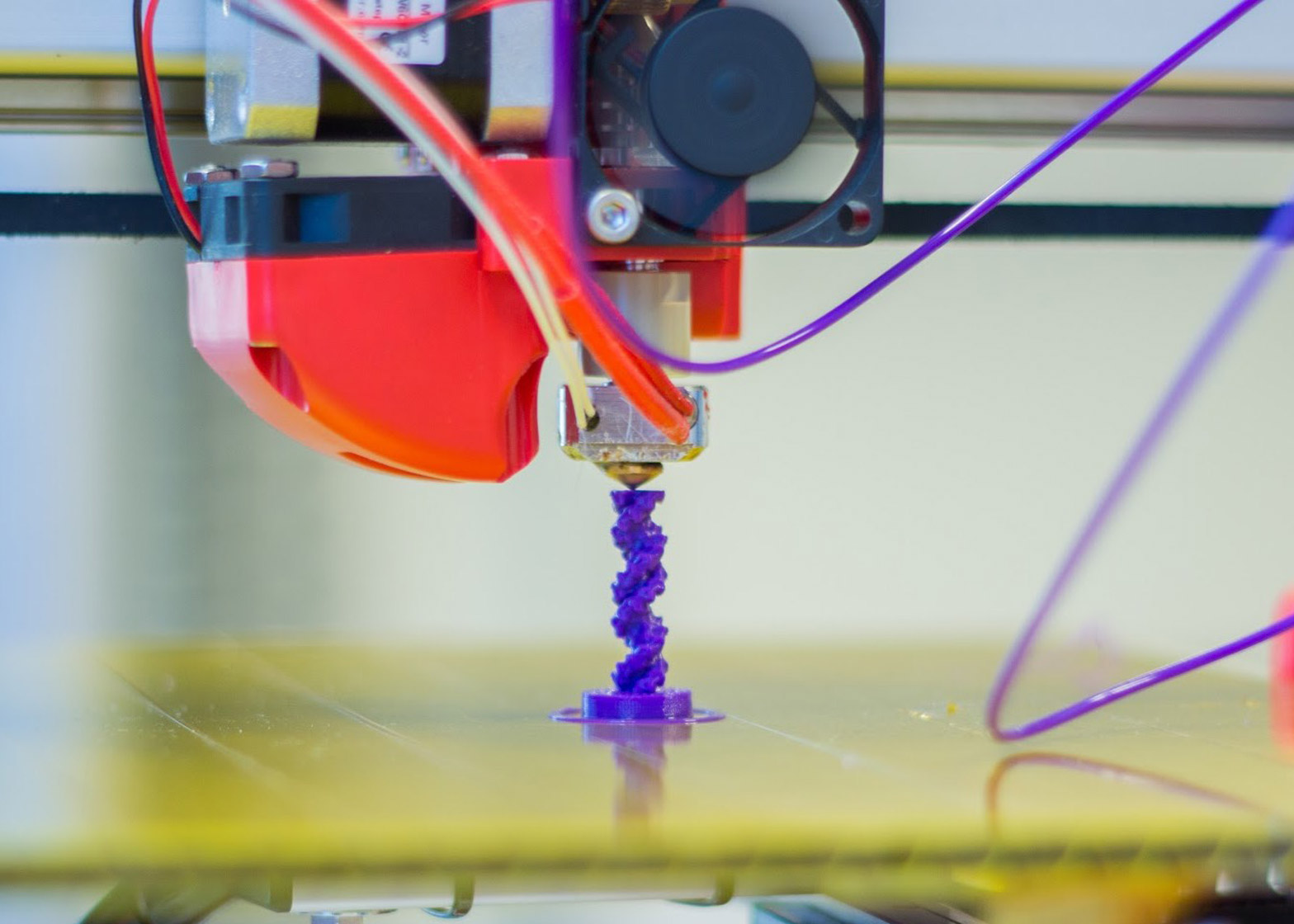

Basically the same one I have.. dump the right extruder..up the speed and let it go.

I may consider one extruder as spare parts, but the prospect of printing two colors simultaneously fits my needs, too. Should this workout as I hope, I may buy a Creality CR-10 for larger projects. If speed becomes a factor, I'll get a delta style printer.

Which Replicator-ish model do you have? Have you upgraded anything for better prints, reliability or to extend the capability? I plan to print PLA and exotics (CF), but not much ABS. Of course, plans are always meant to be changed.

Untitled

Untitled